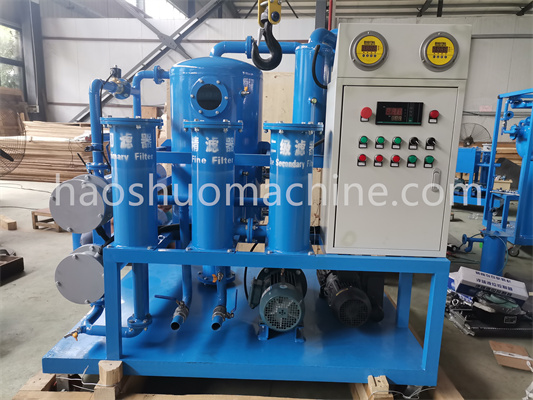

Transformer Oil Filtration Machine

Transformer Oil Filtration Machine (Oil Purifier) is designed for filtration and purification of electrical insulating oil. It can remove water contents, gases and moistures, solid contaminations, recovering the oil dielectric strength (BDV), at the same time reducing the speed of oil ageing. The machine is very effective, durable, and user-friendly transformer insulating oil equipment. It is also applied for maintain oils used in other electrical equipment, such as regulator, reactor, circuit breaker, switchgear, etc.

READ MORE