Features

1.We have series of slitting lines, with thickness of 0.1-25mm and width up to 2500mm.

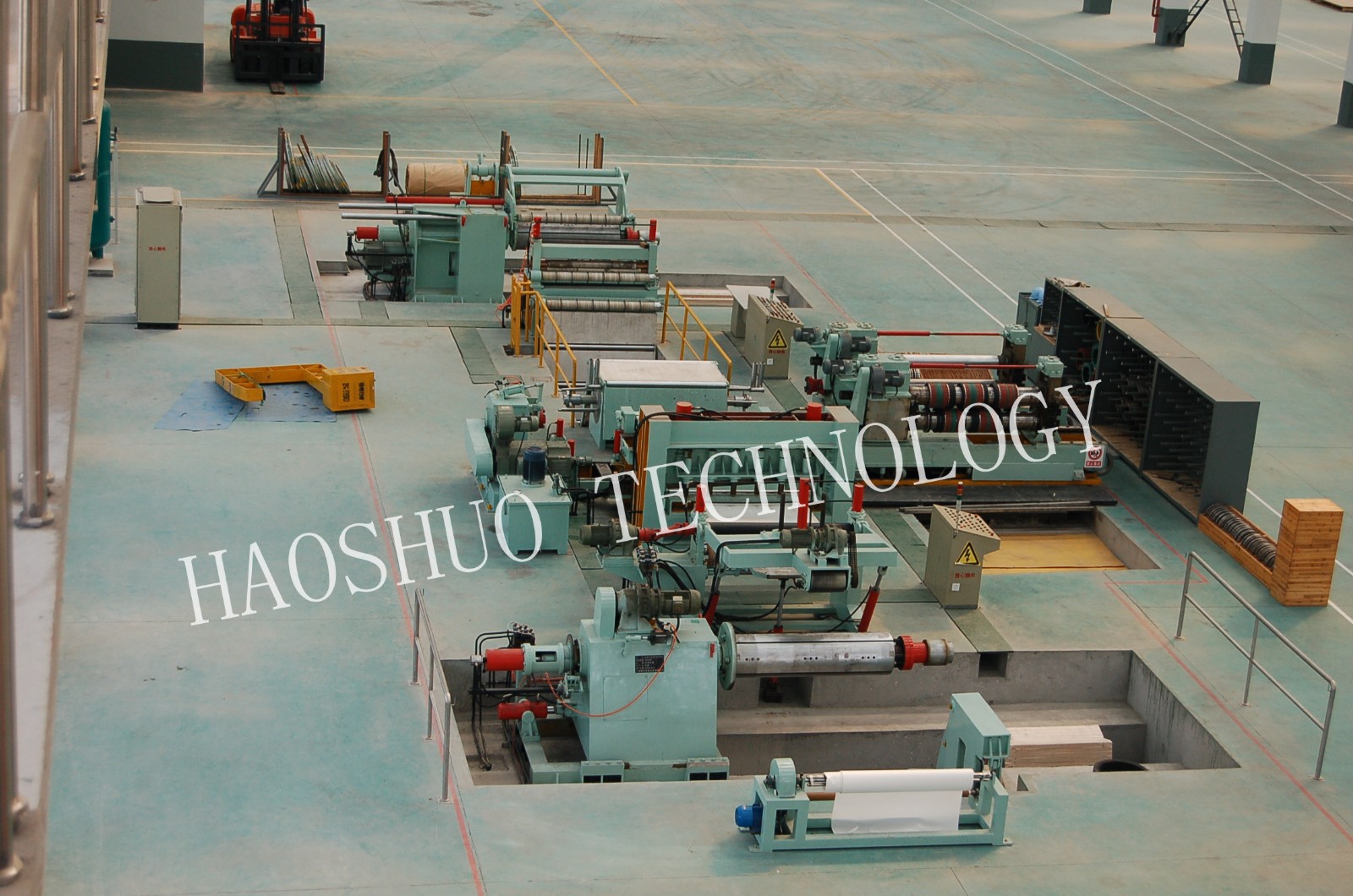

2. The main components are decoiler, coil open device, feeder, slitting machine, scrap winder, recoiler, and PLC control system, etc.

3. The steel slitting machine has got the relevant requirements of ISO9001:14000 and CE standards, etc.

4. Our slitting line has reached the leading domestic level and it is a famous brand in China.

Work Flow of Steel Slitting Line

Entry coil car→ un-coiler→ entry guides → pinch roll feeder & 5-roll flattener→ entry crop shear → centering device→ rotary slitter→ scrap winder→ loop table & buffer pit→ pre-separating and tension stand→ re-coiler→ exit coil car

Operation and Attention

1. Operator number should be 2 to 5 workers, and other people should keep away from this equipment

2. Around the equipment, there should be yellow caution color to indicate off-limits place

3. Please do well lubrication for gears and chains.

4. Coil should be put right to keep the weight balanced. The coil car can reset only after fix and expand the coil into decoiler tightly.

5. First press the coil head by traction roll, then open the package of the coil, to prevent the coil head bounced off.

6. Operators shall not stand on the coil when machine running.

7. Do not move coil directly by hand.

8. Stop and check the machine units immediately when find fault. Only check out and correct, the machine can restart.

9. Do not remove or change circuit. In case of any problem, please consult professional technicians.

Packaging and Transportation

This steel slitting line should adopt sea shipping by container. If there is no special requirement, this machine usually utilizes nude packaging, with cable wire and wooden block fastening it. All gadgets should be placed in accessory steel box.

Maintenance and Lubrication

1. Check steel slitting machine units whether loosen or damaged and check electrical parts, hydraulic parts, and pneumatic parts whether abnormal after work finished. If so, should adjust or repair immediately.

2. Check the oil pipes are smooth, regular filling oil. (lubricating list)

3. Cut off main power, clean up machine units after work finished.

4. Regularly inspect machine to ensure proper operation.

Parameters of Steel Slitting Line

|

Raw material

|

hot rolled steel, cold rolled steel, galvanized sheet, etc.

|

|

Thickness

|

1 to 6mm or as per request

|

|

Width

|

max.1600/1800/2000mm

|

|

Max coil weight

|

25 to 35 ton

|

|

Slitting strip

|

min.40mm

|

|

Slitting strips

|

design as per need

|

|

Slitting tolerance

|

±0.1mm

|

|

Power source

|

AC380V±10%/50Hz, or as per Buyer’s requirement

|

|

Main power

|

about 350kW

|

|

Machine outline(L×W)

|

about 35M×8M

|

|

Total weight

|

about 75 tons

|