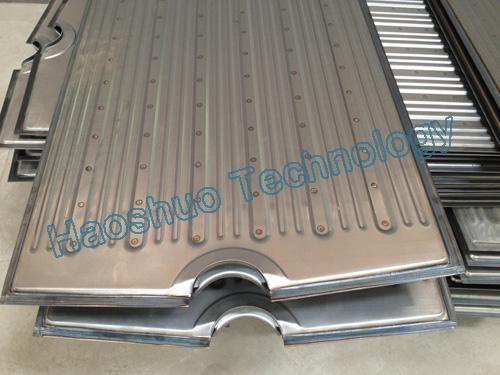

Description

This radiator production line can be used in producing different specification transformer radiators; with width among 535, 520, 480, 460, 320, 310 and center distance from 500mm to 4000mm. This machine has high automation degree, high forming quality, and high efficiency.

Work Flow

automatic decoiling – roll forming – hydraulic punching and cutting – spot welding – seam welding – panel head welding– edge shearing – head cutting– run-out.

Properties

1. Compared with similar lines, this radiator production line is fully automatic. Properties of its products have reached world-class quality.

2.This line has features of high production efficiency and low labor cost. This line can manufacture many different specification products.

3.PLC controls all the welding procedures, and both welding quality and efficiency are very high.

4. The main components of the radiator production line are automatic decoiler, roll forming machine, leveler, oil press machine, press mould, series welding machines, edge shearer, head cutter, product conveyer, pneumatic system, hydraulic system, and electric system.

Operation and Attention

The whole radiator production line is automatically controlled by PLC. Users can start the line to manufacture only by inputting product length.

Maintenance and Lubrication

Users should regularly do lubrication for pneumatic device, and oil press machine, etc. Since there are many welding equipment in the line, users should often check working conditions of every equipment.

Packaging and Transportation

This radiator production line adopts sea shipping by container and nude packaging.

Parameters of Radiator Production Line

|

Item

|

Data

|

|

Standard panel size

|

310mm, 320mm, 460mm, 480mm, 520mm, 535mm, etc

|

|

Panel length

|

500 to 4000mm

|

|

Length tolerance

|

±1.0mm

|

|

Panel bearing pressure

|

Positive pressure≥ 0.15Mpa, negative pressure ≥ 133Kpa, without deformation

|

|

Panel material

|

ST12, SPCC, DC01 cold rolled steel, 1.0 to 1.2mm

|

|

Total power

|

Approx 315kW

|

|

Total line dimension

|

46.5m × 3.5m

|

|

Oil fluits size

|

Steel thickness 1.0mm

|

≥ 11mm

|

|

Steel thickness 1.2mm

|

≥ 11.5mm

|

|

Number of oil fluits

|

Panel 310mm, 320mm

|

3

|

|

Panel 460mm, 480mm

|

5

|

|

Panel 520mm, 535mm

|

6

|

|

Input coil

|

Panel 310mm

|

325mm

|

|

Panel 460mm

|

475mm

|

|

Panel 520mm

|

535mm

|